Renewable Design for Machining Precision Parts - Metal Stamping And Forming | Precision Stamping – Retek

Renewable Design for Machining Precision Parts - Metal Stamping And Forming | Precision Stamping – Retek Detail:

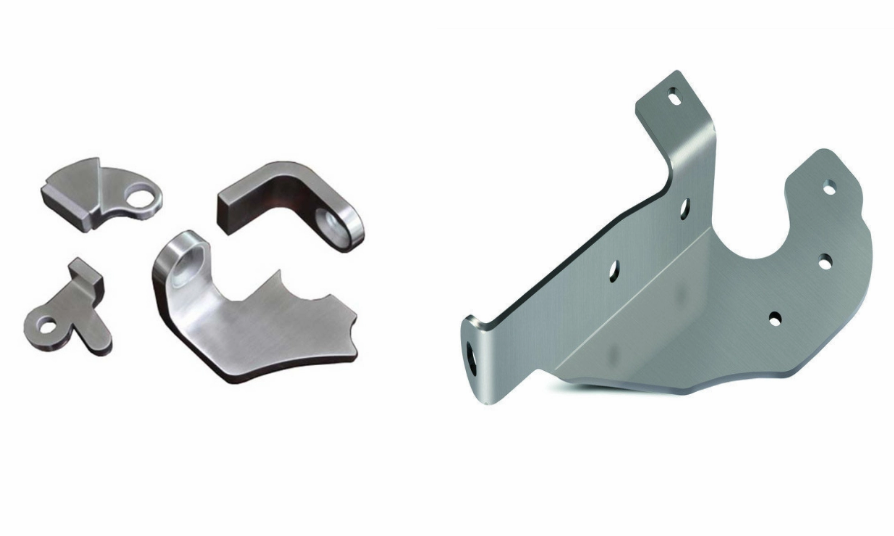

✧ Product Introduction

Zinc alloy has the advantages of low melting point, small solidification temperature range, easy filling and forming, small shrinkage tendency, and can be used to die cast precision parts with complex shape and thin wall, with smooth casting surface and high dimensional accuracy; low pouring temperature, long service life of the mold, not easy to stick and corrosion of the mold. Moreover, the mechanical properties of zinc alloy at room temperature are also high, especially the compression resistance and wear resistance are very good. Zinc alloy die castings can well accept various surface treatments, such as electroplating, spraying, painting and so on.

✧ Products Description

| Mold Material | SKD61, H13 |

| Cavity | Single or multiple |

| Mold Life Time | 50K times |

| Product Material | 1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24 2) Zinc alloy 3#, 5#, 8# |

| Surface Treatment | 1) Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodine 2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating |

| Size | 1) According to customers’ drawings 2) According to customers’ samples |

| Drawing Format | step, dwg, igs, pdf |

| Certificates | ISO 9001: 2015 & IATF 16949 |

| Payment Term | T/T, L/C, Trade Assurance |

Product detail pictures:

Related Product Guide:

We consistently carry out our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management promoting benefit, Credit attracting customers for Renewable Design for Machining Precision Parts - Metal Stamping And Forming | Precision Stamping – Retek , The product will supply to all over the world, such as: Namibia, Latvia, Detroit, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We are able to also provide you with no cost samples to meet your needs. Best efforts will be produced to offer you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our products and enterprise. lot more, you'll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. Please really feel absolutely free to make contact with us for small business and we believe we will share the top trading practical experience with all our merchants.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.

Write your message here and send it to us