Personlized Products Zinc Alloy Die Casting Manufacturers - Zinc Alloy Die-Casting Parts | Professional OEM Die Casting – Retek

Personlized Products Zinc Alloy Die Casting Manufacturers - Zinc Alloy Die-Casting Parts | Professional OEM Die Casting – Retek Detail:

✧ Product Introduction

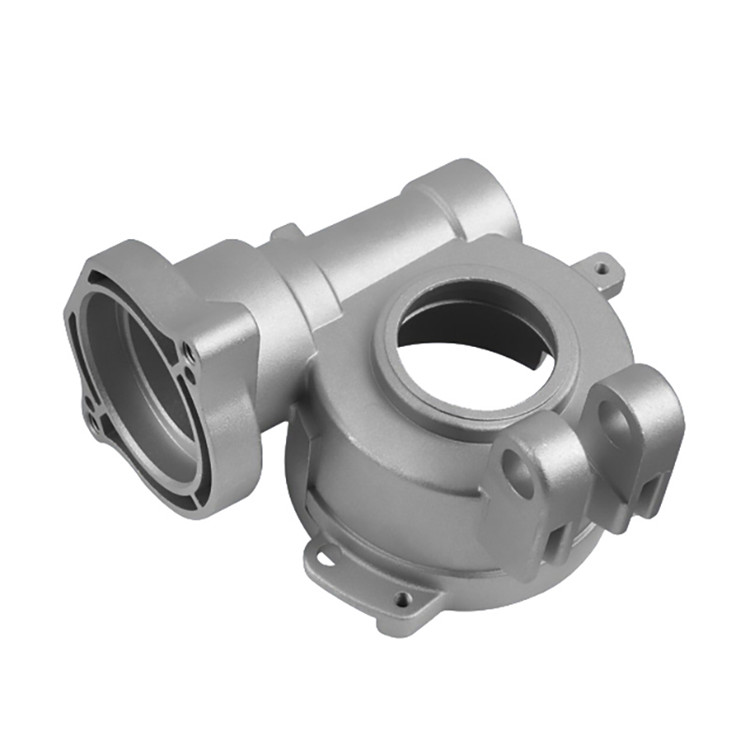

Zinc die castings are used to produce various parts and components in many types of industrial applications. The mechanical properties of zinc alloy die castings at room temperature are better than those of gray iron, brass and aluminum sand castings, especially in terms of toughness and impact strength. They are stronger, tougher and more dimensionally stable than injection molded plastics. Reduced cost and improved performance make it an ideal substitute for iron, copper, aluminum alloy or plastic parts.

Advantages of zinc alloy die casting

1. Improved casting properties – due to its fluidity, zinc die castings can be made thinner, more complex and more complex, thus eliminating the need for secondary processing that usually must be done with aluminum and magnesium alloys.

2. Shorten the cycle time – due to the hot-chamber casting process for zinc, the output is about 4 to 5 pieces per minute. Compared with the aluminum cold chamber die casting process (outputting 2 to 3 sheets per minute), it can be determined that zinc can increase the total savings due to the shortened cycle time.

3. Extend the life of the mold – due to the low melting temperature of zinc, the life of the mold of zinc parts can be 10 times longer than that of aluminum alloy castings, and about 5 times longer than that of magnesium molds.

4. Ideal mechanical quality – zinc alloy is stronger than other similar metals and does not require secondary processing. This quality saves the total cost of each part.

✧ Products Description

| Mold Material | SKD61, H13 |

| Cavity | Single or multiple |

| Mold Life Time | 50K times |

| Product Material | 1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24 2) Zinc alloy 3#, 5#, 8# |

| Surface Treatment | 1) Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodine 2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating |

| Size | 1) According to customers’ drawings 2) According to customers’ samples |

| Drawing Format | step, dwg, igs, pdf |

| Certificates | ISO 9001:2015 & IATF 16949 |

| Payment Term | T/T, L/C, Trade Assurance |

Product detail pictures:

Related Product Guide:

We generally believe that one's character decides products' top quality, the details decides products' high-quality ,along with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Personlized Products Zinc Alloy Die Casting Manufacturers - Zinc Alloy Die-Casting Parts | Professional OEM Die Casting – Retek , The product will supply to all over the world, such as: Belgium, Congo, Leicester, Our expert engineering team will generally be prepared to serve you for consultation and feedback. We're able to also give you with free of charge samples to meet your requirements. Best efforts will likely be produced to provide you the best service and merchandise. When you are keen on our business and items, make sure you speak to us by sending us emails or call us quickly. In an effort to know our merchandise and company extra, you may come to our factory to view it. We'll generally welcome guests from all over the world to our business to create business relations with us. Be sure to feel cost-free to speak to us for small business and we believe we are going to share the best trading experience with all our merchants.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.