Personlized Products Zinc Alloy Die Casting Manufacturers - Customized Zinc Alloy Die Castings – Retek

Personlized Products Zinc Alloy Die Casting Manufacturers - Customized Zinc Alloy Die Castings – Retek Detail:

✧ Product Introduction

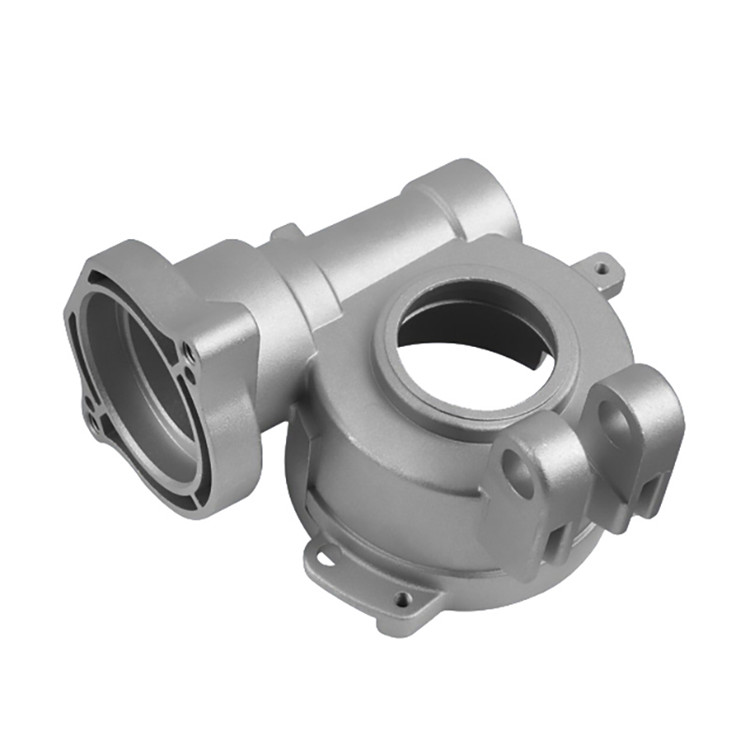

Customized Zinc Alloy Die Castings

High pressure zinc alloy die casting is one of the most effective and universal high yield methods for manufacturing solid, accurate and complex metal parts. It has higher strength and useful bearing characteristics. It is carried out in an automatic machine suitable for withstanding high pressure. The mechanical properties of zinc die castings are generally superior to other casting processes because of the rapid cooling and solidification of molten metal when it comes into contact with the relatively cold steel surface.

Our alloys include:

Zinc: Zamak 3, 5, and 7

Zinc-Aluminum: ZA-8, ZA-12, and ZA-27

Zinc alloys are the easy to high pressure diecast. They offer high ductility, impact strength, and can be easily plated. Zinc alloys have a lower melting point than aluminum which can assist in improving die life.

ZA alloys are zinc-based die casting materials that have a higher aluminum content than standard zinc alloys. These alloys has high strength characteristics also high hardness and well bearing properties.

Teknic uses the internationally recognized CAM simulation technology to optimize tool design and zinc casting quality.

CAM simulation capabilities provide a better understanding of zinc injection mold filling, solidification, mechanical properties, thermal stresses and distortions. Fully menu-driven with an integrated solid modeler, CASD interfaces, and extensive databases, CAM provides a complete solution for design, production, and quality departments.

✧ Products Description

| Mold Material | SKD61, H13 |

| Cavity | Single or multiple |

| Mold Life Time | 50K times |

| Product Material | 1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24 2) Zinc alloy 3#, 5#, 8# |

| Surface Treatment | 1) Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodine 2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating |

| Size | 1) According to customers’ drawings 2) According to customers’ samples |

| Drawing Format | step, dwg, igs, pdf |

| Certificates | ISO 9001:2015 & IATF 16949 |

| Payment Term | T/T, L/C, Trade Assurance |

Product detail pictures:

Related Product Guide:

Always customer-oriented, and it's our ultimate target to be not only the most reliable, trustable and honest supplier, but also the partner for our customers for Personlized Products Zinc Alloy Die Casting Manufacturers - Customized Zinc Alloy Die Castings – Retek , The product will supply to all over the world, such as: Algeria, Macedonia, Macedonia, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Make sure you your inquiry for more details or request for dealership in selected regions.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!