Aluminum die casting base and aluminum alloy die casting are two key components in the manufacturing industry, especially in industries that require lightweight and durable materials. The combination of these two processes can not only improve product performance, but also optimize production efficiency.

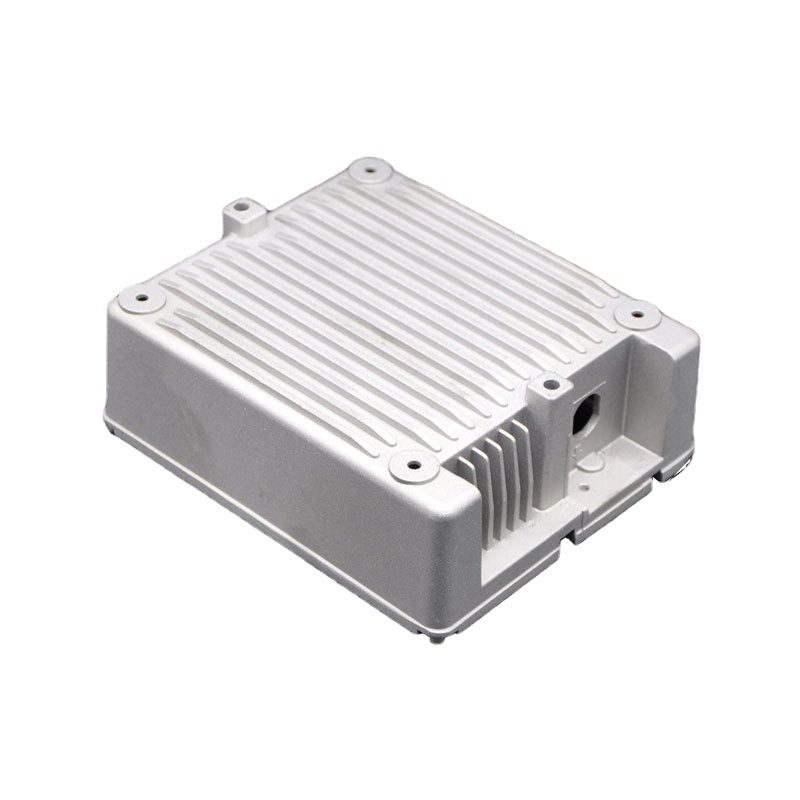

Aluminum die-cast housings are designed to provide a sturdy foundation for a variety of applications, from automotive parts to electronic housings. The die-casting process involves injecting molten aluminum into a mold, allowing for complex designs and precise dimensions. This method is particularly advantageous for creating complex shapes that are difficult to achieve with traditional manufacturing techniques. On the other hand, aluminum alloy die casting takes the advantages of aluminum shell die casting a step further. By adding various alloying elements, manufacturers can enhance the mechanical properties of aluminum, such as its corrosion resistance, thermal conductivity and overall strength. The synergy between the aluminum die casting matrix and aluminum alloy die casting is evident in its applications. For example, in the automotive industry, these components are used to create lightweight vehicle frames and engine parts, helping to improve fuel efficiency and performance. In electronics, this combination allows the production of heat sinks and housings that protect sensitive components while effectively dissipating heat.

In summary, the combination of aluminum shell die casting base and aluminum alloy die casting represents a major advancement in manufacturing technology. This combination not only meets the demand for lightweight and durable materials, but also paves the way for innovative designs and applications in various industries.

Post time: Mar-20-2025