Low MOQ for Home Electric Casting - Metal Stamping And Forming | Precision Stamping – Retek

Low MOQ for Home Electric Casting - Metal Stamping And Forming | Precision Stamping – Retek Detail:

✧ Product Introduction

Zinc alloy has the advantages of low melting point, small solidification temperature range, easy filling and forming, small shrinkage tendency, and can be used to die cast precision parts with complex shape and thin wall, with smooth casting surface and high dimensional accuracy; low pouring temperature, long service life of the mold, not easy to stick and corrosion of the mold. Moreover, the mechanical properties of zinc alloy at room temperature are also high, especially the compression resistance and wear resistance are very good. Zinc alloy die castings can well accept various surface treatments, such as electroplating, spraying, painting and so on.

✧ Products Description

| Mold Material | SKD61, H13 |

| Cavity | Single or multiple |

| Mold Life Time | 50K times |

| Product Material | 1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24 2) Zinc alloy 3#, 5#, 8# |

| Surface Treatment | 1) Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodine 2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating |

| Size | 1) According to customers’ drawings 2) According to customers’ samples |

| Drawing Format | step, dwg, igs, pdf |

| Certificates | ISO 9001: 2015 & IATF 16949 |

| Payment Term | T/T, L/C, Trade Assurance |

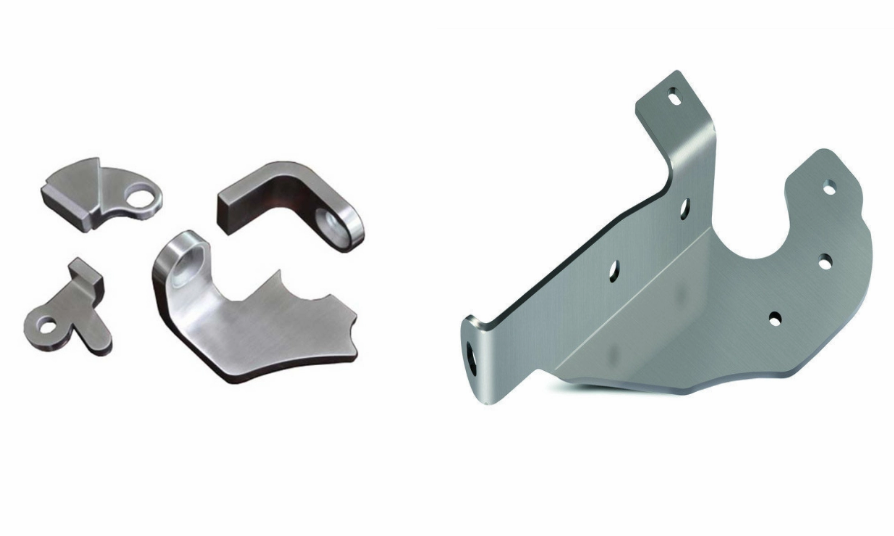

Product detail pictures:

Related Product Guide:

we can easily offer you high-quality products and solutions, competitive rate and very best shopper support. Our destination is "You come here with difficulty and we give you a smile to take away" for Low MOQ for Home Electric Casting - Metal Stamping And Forming | Precision Stamping – Retek , The product will supply to all over the world, such as: Karachi, Manila, Bogota, Our products are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.

Write your message here and send it to us