CNC Milling

CNC Milling provides precise, repeatable machining for complex parts using advanced multi-axis equipment and a wide range of materials.

CNC Milling

CNC milling is a computer-controlled, subtractive machining process that uses rotating cutting tools to remove material from a solid, stationary workpiece in order to create custom-designed parts. During the milling process, the workpiece is cut along a number of axes to achieve a variety of shapes and geometries. CNC mills can be used for cutting and machining operations of various plastic and metal materials. It is used to manufacture irregular shape products or prototypes. It is widely used for many industries that requires precision components and is also an ideal tool for making molds.

Retek CNC Milling Capabilities

We offer custom CNC milling services for a wide variety of plastics and metals. With our 3-axis and 5-axis CNC machining center, we can produce a variety of simple and complex CNC milled parts. Whether you need prototypes or massive production parts, we can handle it.

Quick turnaround provide us great competence against others. We also have a variety of surface finish options so that your CNC machined part is exactly what you need it to be.

3-Axis CNC Milling Service

3-axis CNC milling is one of the most widely used techniques to make mechanical parts. For decades, it has been well known to manufacturers and other players in the industrial sector, as well as in many other domains like architecture, design, and art.

3-axis milling is a relatively simple process, using conventional machining tools like the milling machine, which allows the material to be worked on 3 axes (X,Y and Z). The machining tool then proceeds to remove shavings in three basic directions corresponding to the axis of a flat surface. It involves cutting a stationary workpiece along three linear axes: left-to-right, back-and-forth, up-and-down. Easy to program and operate, 3-axis mills are effective for simple geometric designs and can be used for a wide variety of parts because it is fast and cost-effective.

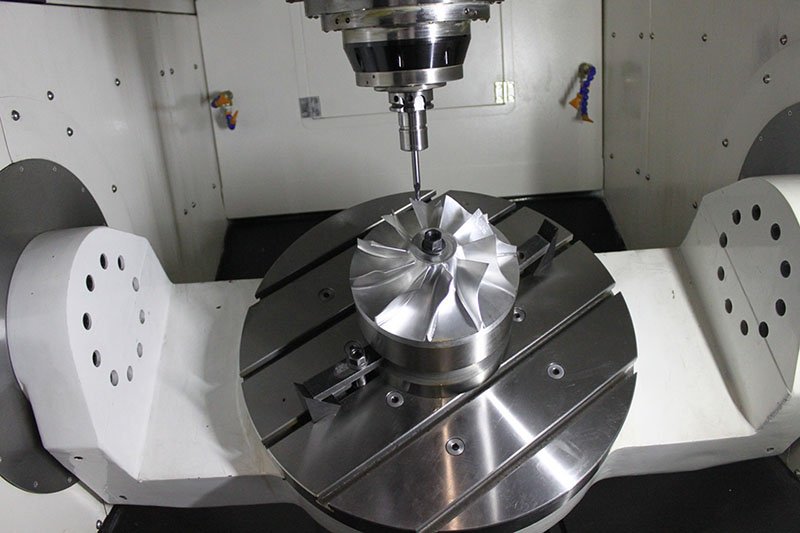

5-Axis CNC Milling Service

5 axis milling involves all the axes of 4 axis milling, with an additional rotational axis. 5 axis milling machines are the best CNC milling machines available today, capable of creating precise and intricate parts for artificial bones, aerospace products, titanium pieces, oil and gas machine parts, car molds, medical, architectural, and military products.

For some complex internal design or models with multi irregular surface design, we will use 5 axis CNC milling machine to produce, to improve the overall accuracy and reduce the processing time and cost.

Our Solutions & Benefits

- 5-axis CNC milling for complex and high-precision components.

- Custom part manufacturing from CAD models to final products.

- Rapid prototyping services with short turnaround times.

- High-volume production runs with consistent quality.

- Machining of various materials including aluminum, steel, brass, and plastics.

- Ensures tight tolerances and excellent surface finish.

- Reduces lead time and accelerates product development.

- Offers flexibility for both simple and intricate designs.

- Increases cost-efficiency for large production batches.

- Maintains consistent quality with ISO-certified processes.

Get a Quote

Don’t hesitate to contact us for more information.

Need more help?

Have more questions? Our expert team is here to support you anytime.

+86-512-68769967

Typical Materials for CNC Milling

| Plastic | Aluminum | Stainless Steel | Other Steel | Other Metal |

| ABS | 2024 | 303 | Mid-Steel | Brass |

| Nylon 6 | 6061 | 304 | Alloy Steel | Copper |

| Acetal (Delrin) | 7050 | 316 | Tool Steel | Titanium |

| Polycarbonate | 7075 | 17-4 | ||

| PVC | 420 | |||

| HDPE | ||||

| PTEE(Teflon) | ||||

| PEEK | ||||

| Nylon 30%GF | ||||

| PVDF |

Available Surface Treatment Options

Surface finishes are applied after milling and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts. Below are the mainstream surface finish types.

| As machined | Polishing | Anodized | Bead Blasting |

| Brushing | Screen Printing | Heat Treating | Black Oxide |

| Powder Coating | Painting | Engraving | Plating |

| Brushing | Plating | Passivating |

High Accurancy

We have realized tight tolerance down to +/-0.001″ – 0.005″.

Diversified Options

Over 40 metal and plastic materials and a wide type of surface finish for your choice.

Economy & Efficiency

Precise repeatable production exactly matches per specification,

extremely saving your time and production cost.

Constant Consistency

With our superior milling machines and optimized milling workflow,

you can obtain a physical copy of your digital.

Typical Application of CNC Milling Parts

If you are looking for a CNC milling company or a CNC machine shop to fabricate small, medium volume, or mass production products, Retek is an ideal choice. Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC milling machines, with the highest accuracy and processing quality in all sizes. In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest milling service? Upload your CAD files now and obtain a CNC milled parts quote!

Common Questions

Most Popular Questions.

Explore answers to the most frequently asked questions about CNC milling, precision, materials, and more.

CNC milling is a subtractive manufacturing process that uses computer-controlled rotating tools to remove material from a workpiece.

CNC milling can process a wide range of materials including aluminum, stainless steel, brass, copper, plastics, and composites.

Standard tolerances range from ±0.01mm to ±0.05mm, but tighter tolerances are possible for precision components.

Lead times vary depending on part complexity and quantity but typically range from a few days to two weeks.

Yes, we offer CNC milling services for both rapid prototypes and high-volume production runs with consistent quality.