2022 New Style Led Radiator Processing - Metal Stamping And Forming | Precision Stamping – Retek

2022 New Style Led Radiator Processing - Metal Stamping And Forming | Precision Stamping – Retek Detail:

✧ Product Introduction

Zinc alloy has the advantages of low melting point, small solidification temperature range, easy filling and forming, small shrinkage tendency, and can be used to die cast precision parts with complex shape and thin wall, with smooth casting surface and high dimensional accuracy; low pouring temperature, long service life of the mold, not easy to stick and corrosion of the mold. Moreover, the mechanical properties of zinc alloy at room temperature are also high, especially the compression resistance and wear resistance are very good. Zinc alloy die castings can well accept various surface treatments, such as electroplating, spraying, painting and so on.

✧ Products Description

| Mold Material | SKD61, H13 |

| Cavity | Single or multiple |

| Mold Life Time | 50K times |

| Product Material | 1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24 2) Zinc alloy 3#, 5#, 8# |

| Surface Treatment | 1) Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodine 2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating |

| Size | 1) According to customers’ drawings 2) According to customers’ samples |

| Drawing Format | step, dwg, igs, pdf |

| Certificates | ISO 9001: 2015 & IATF 16949 |

| Payment Term | T/T, L/C, Trade Assurance |

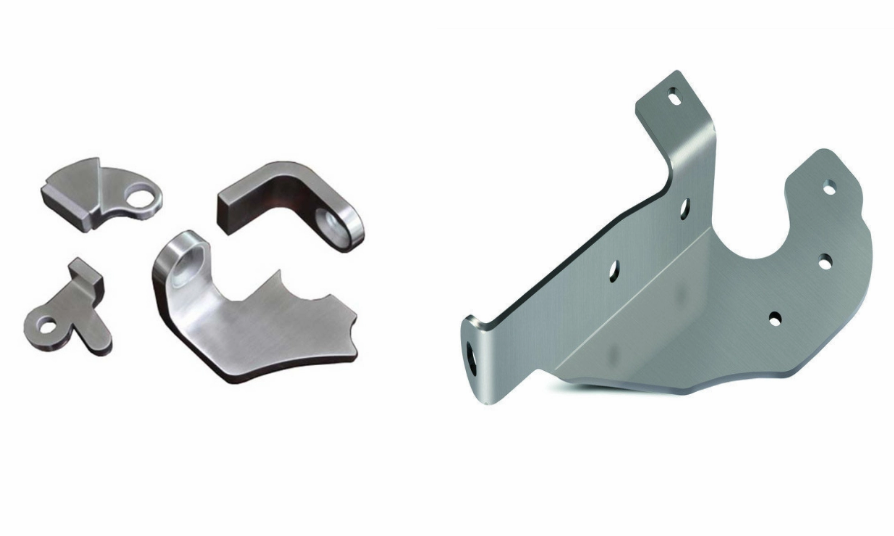

Product detail pictures:

Related Product Guide:

Adhering into the basic principle of "quality, assistance, effectiveness and growth", we have attained trusts and praises from domestic and worldwide client for 2022 New Style Led Radiator Processing - Metal Stamping And Forming | Precision Stamping – Retek , The product will supply to all over the world, such as: Qatar, Vietnam, Bangladesh, Faced with the vitality of the global wave of economic integration, we are confident with our high-quality products and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.

Write your message here and send it to us